Competing against industry giants made possible through implementation of clever lifting automation by small manufacturers

Small and growing manufacturers can significantly improve their productivity and competitiveness by adopting smart lifting automation solutions. These technologies, which range from collaborative robots (cobots) and robotic palletisers to simple, space-saving tools like Wall Mounted JIB Cranes and Electric Chain Hoists, offer numerous benefits that can help SMEs thrive in today's fast-paced manufacturing environment.

Manual material handling in small workshops can limit productivity, introduce safety risks, lead to worker fatigue, and prevent efficient scaling. By automating even one part of their material handling process, small manufacturers can achieve big wins. Smart lifting solutions can speed up production by reducing material movement time by 30-50%, reduce injuries by minimizing worker fatigue and OSHA violations, save floor space, and boost consistency by automating repetitive lifting with motorized hoists.

One of the key advantages of smart lifting automation is increased productivity. SMEs have reported productivity gains ranging from 15% to 50% after automation implementation. Automation technologies like cobots and robotic palletisers help increase output, enabling manufacturers to take on more orders and grow their business.

Another significant benefit is a faster return on investment (ROI). Many SMEs achieve ROI within 6 to 18 months due to increased efficiency and cost savings. The investment in small cranes and hoists often has a faster ROI, with most SMEs recovering the investment within 6-12 months through labor savings and improved efficiency.

Smart lifting solutions also improve consistency and quality. Automated lifting and palletising systems reduce manual handling errors and improve consistency in processes like pallet formation and load stability, which are important for meeting customer compliance requirements.

In addition, smart lifting automation helps reduce workplace injuries. Robotic automation eliminates the strain and risks associated with manual heavy lifting, helping improve workplace safety.

Modern robotic lifting and palletising systems are designed to integrate quickly with existing legacy or modern manufacturing lines with minimal downtime. This seamless integration enables SMEs to adopt automation solutions without disrupting their operations.

Employee satisfaction and redeployment are also positive outcomes of smart lifting automation. Offloading repetitive and strenuous lifting tasks to robots frees operators to focus on higher-value roles, improving job satisfaction and optimizing workforce deployment.

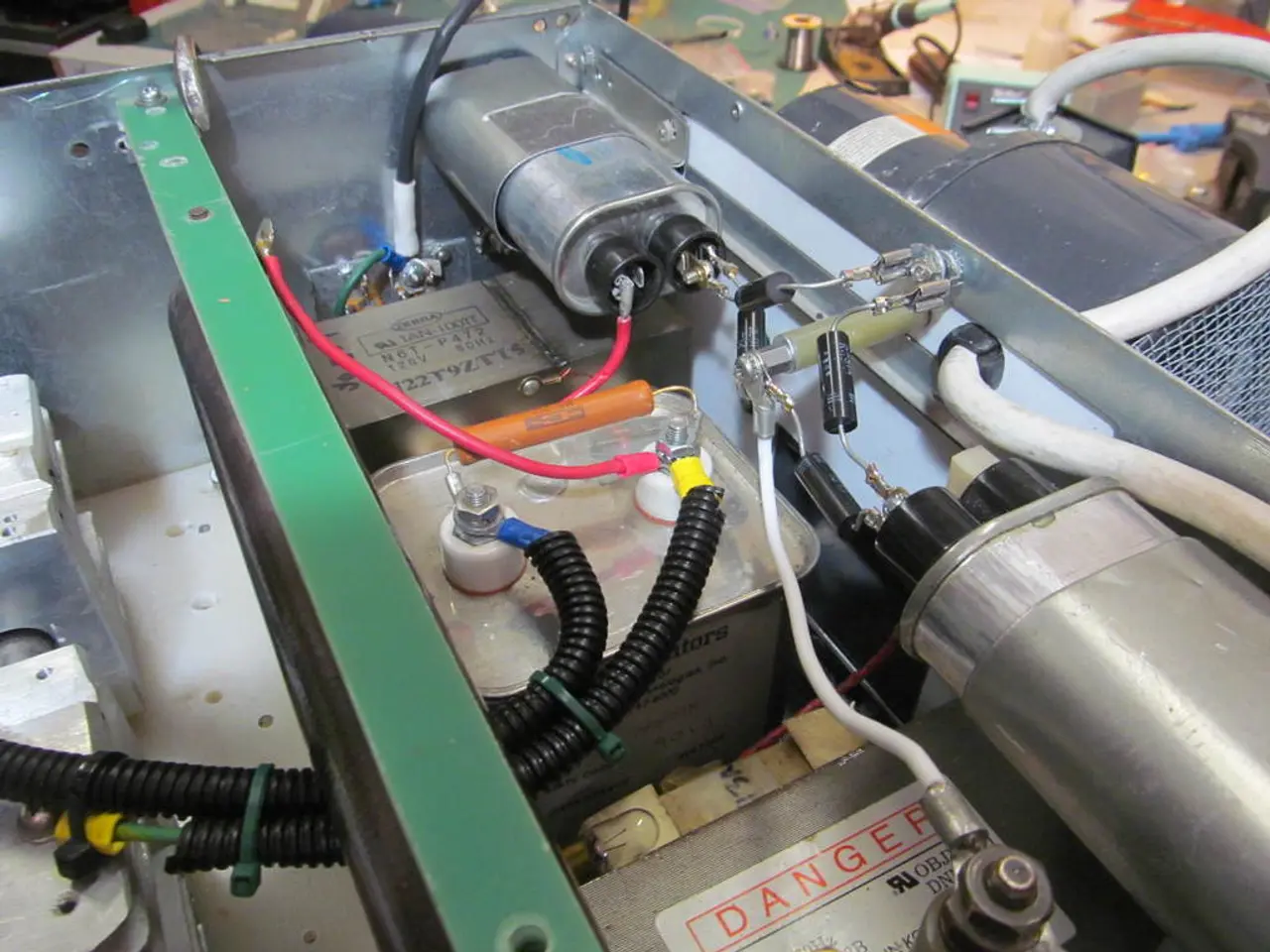

Numerous SME case studies confirm these advantages across sectors like metal fabrication, electronics, e-commerce fulfillment, and precision machining. For example, a small manufacturer in Gujarat, India, producing heavy steel brackets, reduced internal transport time by 40% and increased shift throughput without hiring additional staff after installing a Pillar Mounted JIB Crane with a Loadmate Electric Hoist.

Government and industry initiatives like Made Smarter provide SMEs with support for adopting such technologies through grants, strategic advice, and training, accelerating digital transformation and automation adoption in manufacturing.

In summary, smart lifting automation offers tangible benefits to SMEs in manufacturing by improving productivity, safety, and quality while enabling faster ROI and workforce optimization. Platforms like Maker's Row can streamline the process of upgrading equipment or sourcing parts locally for small manufacturers, making it easier for them to take advantage of these benefits.

Adopting smart lifting automation technologies, such as collaborative robots (cobots) and pillar-mounted JIB cranes, can enhance productivity and quality in small workshops, with numerous SMEs reporting productivity gains of up to 50% after implementation. By integrating quickly with existing manufacturing lines, these technologies can accelerate digital transformation and achieve a fast return on investment.

Automation systems, like robotic palletisers, minimize manual handling errors, improve consistency in processes, and reduce workplace injuries associated with heavy lifting, hence contributing to improved workplace safety and quality. Government and industry initiatives, like Made Smarter, provide support for SMEs adopting such technologies, thereby facilitating their digital transformation and automation adoption in manufacturing.