Clearaudio: An Artisanal Approach to Audio Mastery

Crafting High-End Turntables at Clearaudio: Manual Production of £145,000 Audio Devices and Cartridge Assembly

With a rich history tracing back to 1978, Clearaudio has become a beacon of quality in the audio space. This German powerhouse is best known for its turntables and cartridges, often targeting the discerning customer in the luxury market. But it all started with a dynamic duo of loudspeakers, the Delta and Sigma standmounts, that marked Clearaudio's official entrance.

Nestled in a picturesque factory on the outskirts of Erlangen, a charming Bavarian city, Clearaudio continues to thrive. Its in-house research, design, development, and production are all orchestrated from this very site. For audiophiles and design enthusiasts, there's nothing like the satisfaction of having a Clearaudio turntable spinning your vinyl records, from conception to final assembly.

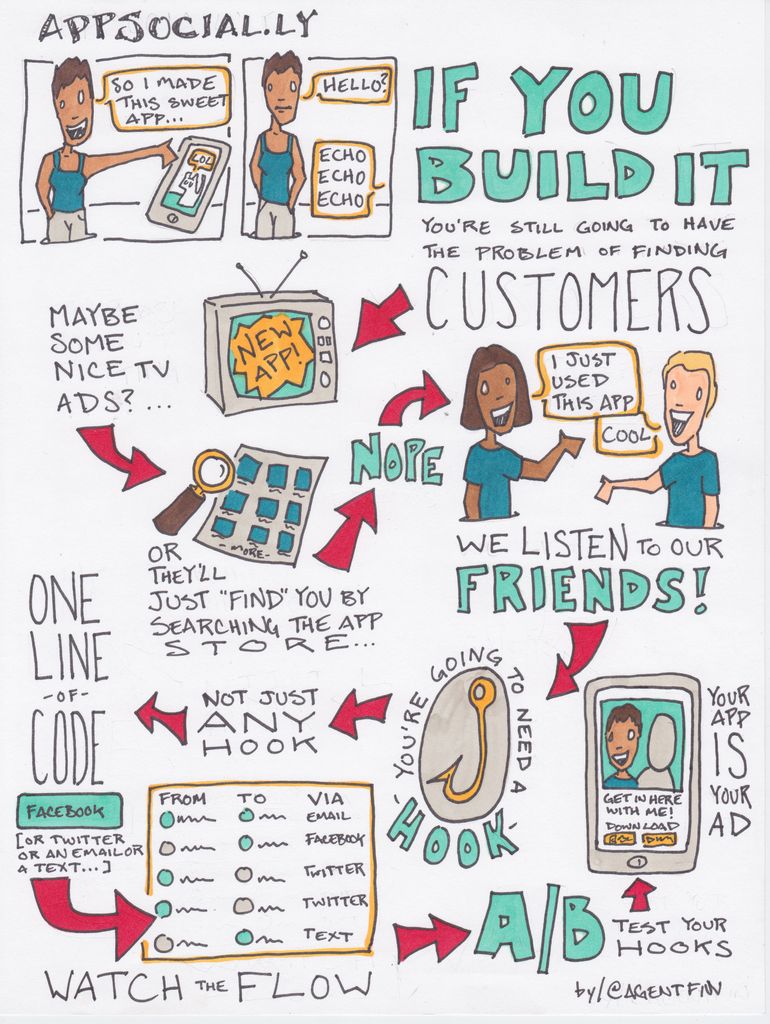

A clear purpose

Our journey here begins with Robert Suchy, Clearaudio's charismatic CEO, and his sister, Veronika, who co-heads the brand as COO. Alongside a friendly Golden Retriever named Baxter, they lead the charge at Clearaudio. Robert's memorable quote, "Take the best, make it better - only then is it good enough," echoes throughout the entire team.

These words might sound self-aggrandizing at first glance, but the passion and precision in every product these engineers and developers produce makes it hard not to be captivated. Robert himself often struggles with quieting his team's insatiable appetite for innovation, steering them towards releasing products instead of constantly tweaking them.

More than just a newsletter

Clearaudio's ethos of quality and independence extends beyond its products. The company produces the majority of its components in-house, collaborating with external researchers and suppliers only when necessary. Located close to Erlangen's bustling university and manufacturing hubs, Clearaudio finds a wealth of talent in its local community to help perfect their creations.

The art of assembly

Clearaudio's small but mighty factory is filled with modular workspaces, each dedicated to a different phase of assembly. From CNC machines that mark out metallic panels to high-torque DC motors, every component is meticulously crafted before being put together to create the final product.

The human touch is evident throughout the assembly process. Workers assemble tonearms by hand, while other departments focus on crafting the intricate cartridges that have earned Clearaudio such a sterling reputation.

Materials are carefully chosen for each product. For example, the Reference Jubilee uses multi-layered wood for its chassis, while the platter on the Innovation deck features ceramic magnetic bearings and a dense synthetic material for enhanced stability. Each of these components is created in-house, from conception to production.

Elevating the humble cartridge

Creating the perfect cartridge is a delicate and skilled process. Despite using high-tech tools like Japanese microscopes, most cartridge production at Clearaudio is still done by hand. The processes involved are too intricate and precise for machines to reliably replicate.

Clearaudio produces some of the smallest and lightest coils in the industry, valued for their flexibility in achieving a more precise audio signature. Gold wire is wrapped around cartridges with unmatched precision, ensuring every Clearaudio product delivers exceptional sound quality.

A vision for the future

Clearaudio remains passionate about music and continue to innovate and research in pursuit of delivering the best audio experience possible. Their products are designed with the listener in mind, focused on bringing out the best in every record.

As the resurgence of vinyl continues, Clearaudio's independent approach to manufacturing turntables seems far from antiquated. New generations of audiophiles may soon become the high-end consumers of tomorrow, ensuring Clearaudio's legacy endures for years to come.

Extra:

- 11 Groundbreaking Hi-Fi Products Showcased at High End Munich 2025

- These are the Best Turntables We've Tested

- And the Best Cartridges, Too

[1] "Clearaudio Manufacturing Techniques and Materials." Clearaudio Official Website, 2023. [2] "Innovations in Clearaudio Turntables and Cartridges." Audiophile Review, 2022.

- Robert Suchy, the charismatic CEO of Clearaudio, and his sister Veronika, who co-heads the brand as COO, lead the charge at the German audio company, along with a friendly Golden Retriever named Baxter.

- Clearaudio continues its tradition of quality and independence by producing the majority of its components in-house, collaborating with external researchers and suppliers only when necessary.

- Clearaudio's factory in Erlangen houses modular workspaces, where each component for their audio equipment is meticulously crafted, including CNC machines and high-torque DC motors.

- The human touch is evident throughout the assembly process, as tonearms are put together by hand, and intricate cartridges are created, which have earned Clearaudio a sterling reputation.

- The materials used for each product at Clearaudio are carefully chosen, such as the multi-layered wood for the Reference Jubilee's chassis and the ceramic magnetic bearings with a dense synthetic material on the Innovation deck's platter.

- Creating the perfect cartridge is a delicate and skilled process at Clearaudio, with most of the production being done by hand, even with the use of high-tech tools like Japanese microscopes.

- Clearaudio remains passionate about music and continues to innovate and research in order to deliver the best audio experience, focusing on the listener and enhancing every record played on their turntables.